Our Services

We are delivering excellence in Coating & Lining Solutions. We specialize in cement lining, internal pipe coatings, glass flake coatings, field joint coatings, valve GRE lining, shotcreting, guniting, and structural fireproofing.

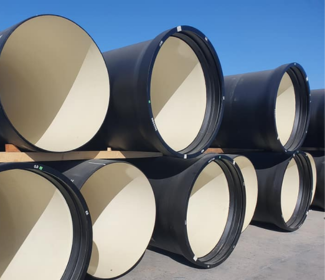

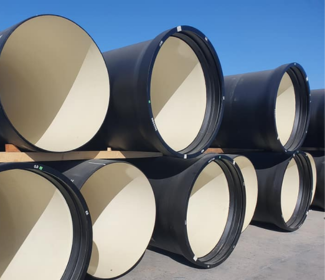

Cement Lining

Cement Lining is a protective process where the interior of pipelines or tanks is coated with cement mortar to prevent corrosion and erosion. Commonly used in oil & gas, water treatment, and industries handling corrosive materials, it offers a cost-effective way to enhance durability, improve flow efficiency, and extend service life.

Key Benefits:

- Prevents internal corrosion & erosion

- Ideal for oil, gas, and water pipelines

- Enhances longevity & reduces maintenance

- Suitable for harsh industrial environments

Internal Pipe Coating

Internal Pipe Coatings (PU Coating) provide a protective layer on the inner surface of pipelines to safeguard against corrosion, abrasion, and chemical attack. These coatings are essential for maintaining the structural integrity and flow efficiency of pipelines used in industries such as oil & gas, water distribution, and chemical processing. Our high-performance polyurethane (PU) coatings offer excellent adhesion, smooth flow surfaces, and long-term protection in aggressive operating environments.

Key Benefits:

- Protects against corrosion, abrasion, and chemicals

- Enhances flow efficiency and reduces friction

- Extends pipeline service life

- Suitable for oil, gas, water, and chemical lines

Glass Flake Coating

Glass Flake Coatings are high-performance protective coatings made from an epoxy resin matrix reinforced with thin glass flakes. Widely used for internal pipe protection, these coatings offer exceptional resistance to corrosion, chemicals, abrasion, and high temperatures. The overlapping glass flakes create a tough, impermeable barrier, making them ideal for harsh environments in marine, offshore, petrochemical, and industrial applications.

Key Benefits:

- Superior resistance to chemicals, heat, and abrasion

- Excellent barrier protection for internal surfaces

- Ideal for pipelines, tanks, and structural steel

- Long-lasting performance in aggressive environments

Field Joint Coating

Field Joint Coatings protect the exposed weld areas of pipelines during installation, where factory coatings are absent. These joints are prone to corrosion and damage, making coating crucial for maintaining pipeline integrity. Our solutions provide durable, seamless protection suitable for both onshore and offshore environments.

Key Benefits:

- Shields weld joints from corrosion and wear

- Maintains full pipeline protection

- Fast application and curing

- Compatible with various pipeline systems

Valve GRE Lining

Valve GRE Lining is a vital process in industrial valve manufacturing, involving the application of Glass Reinforced Epoxy (GRE) or grease-based lining to the valve’s interior. This lining forms a strong protective barrier against corrosive fluids and gases, ensuring smooth operation, extended lifespan, and minimal maintenance. It is especially effective in harsh industrial environments where chemical resistance and durability are critical.

Key Benefits:

- Protects valve interiors from corrosion

- Ensures smooth and reliable operation

- Extends service life in aggressive conditions

- Reduces maintenance and downtime

Shotcreting & Guniting

Shotcreting & Guniting are specialized methods of applying concrete using a high-pressure hose. While shotcreting uses a wet mix and guniting uses a dry mix, both techniques are widely used in construction for structural repairs, walls, floors, roofs, and fire protection. These methods offer excellent adhesion and strength, making them ideal for complex shapes, overhead applications, and areas with limited formwork.

Key Benefits:

- High-strength, durable concrete application

- Ideal for structural reinforcement and repair

- Suitable for complex and overhead surfaces

- Fast application with minimal formwork required

Structural Fireproofing

Structural Fireproofing is essential to both the stability and safety of buildings. It involves applying specialized materials like gypsum-based products, intumescent coatings, and cementitious sprays to structural elements, enabling them to withstand extreme heat and delay collapse during a fire. This process not only protects the building but also gives occupants more time to evacuate and reduces damage.

Key Benefits:

- Enhances structural stability during fires

- Meets building safety and compliance standards

- Uses advanced fire-resistant materials

- Protects lives and minimizes fire damage

Exports

With global reach and quality, we supply cement-lined pipes, internally coated pipes, glass flake-coated components, field joint coatings, and specialized GRE-lined valves to global markets, meeting international quality standards and compliance requirements.

With a strong focus on international standards, we ensure reliable performance and efficient delivery across industries like oil & gas, petrochemicals, marine, and infrastructure.

Key Benefits:

- International quality and compliance

- Reliable global logistics

- Custom solutions for diverse industrial needs

📦 Looking for premium coating and lining solutions for your business? Get in touch with us for export inquiries!

Pipe Yard

Ready to Elevate Your Project?

Whether you’re looking for expert advice or a customized solution, our team is here to help. Contact us today to discuss your requirements and find out how JM Coatings can add value to your project. Let’s build a lasting partnership.